Services

Custom Solutions

Malico is fully engaged with its customers from the design initiation phase all the way to rapid prototyping and production ramping. We offer customized solutions, prompt customer communications, short lead time, and quality assurance to ensure customer product on-time delivery.

DFM Analysis

DFM (Design For Manufacture) analysis is an important process to help our customers to find out the potential problem for the manufacture, yield rate, quality, and lead time. With our DFM analysis, we can shorten the development time, and cost. It can optimize the manufacturing process and decrease lead time and cost and improve quality and reliability.

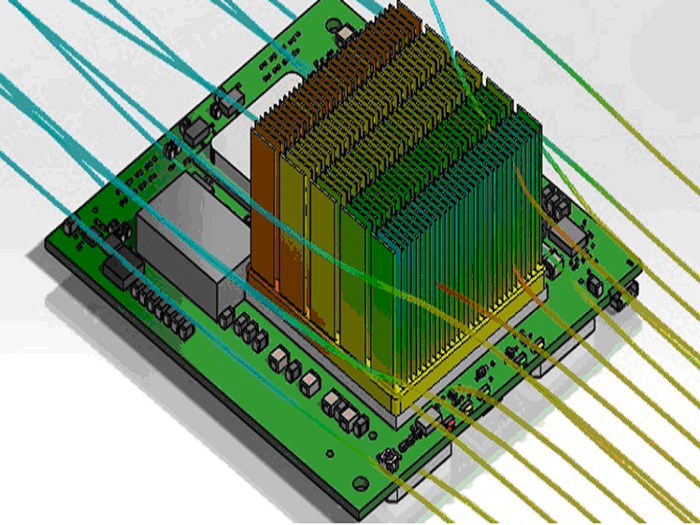

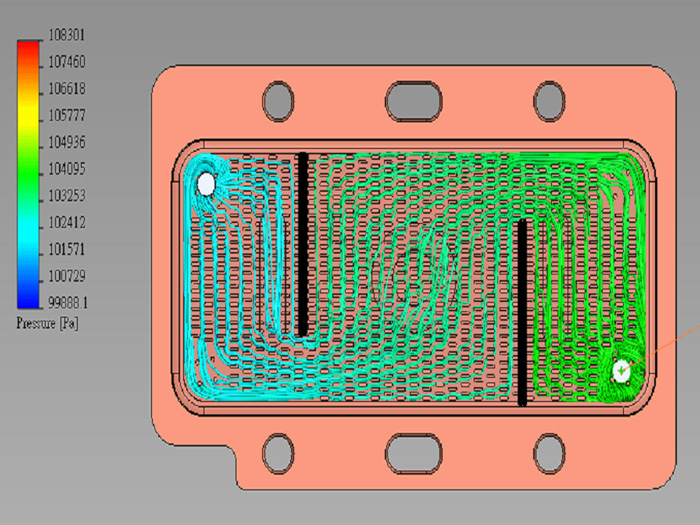

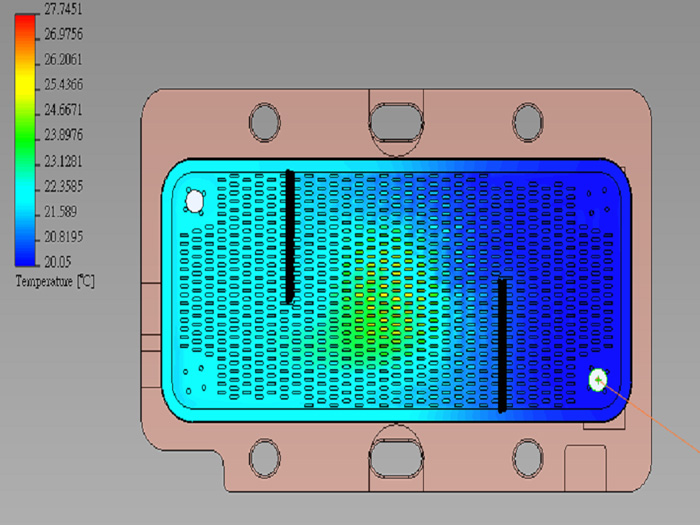

Prototype

Malico provides a 3D file design review and with our product development capacity from our own tooling shop to the surface finishing line. We can provide quick prototyping (if without tooling, a prototype sample in 3-4weeks). We also help to design the heat dissipation solution based on our customer’s requirement.

Production Flexibility

Malico can satisfy its customer’s high-volume and small-volume, large-variety production demand with flexible adjustments. Also, Malico has a tooling shop, forging; die casting; CNC machining, brazing, product assembly lines, and surface finishing lines. By integrating these production processes, we can satisfy our customer’s various production demands. With our aforementioned capabilities, we can control the lead time and satisfy our customer’s requirements.

Product Assembly

We support the hardware assembly and installation of our parts into our customer’s sub-final products. This adds value, saves time, and allows our customers to enjoy cost-saving benefits.