Electronics

5G fiber optics communication system thermal solution

The latest development of 5G has exponentially increased the demand for information exchange. To handle the huge amount of information transmission, it is paramount to the providers to maintain the stability of fiber optic communication. How to adequately dissipate the heat generated from the light engines has become one of the most important efforts in the telecom industry. Malico’s in-depth knowledge and experience in developing thermal management solutions have allowed us to provide the system providers the heat sinks with bigger surface area and smaller footprint for their needs.

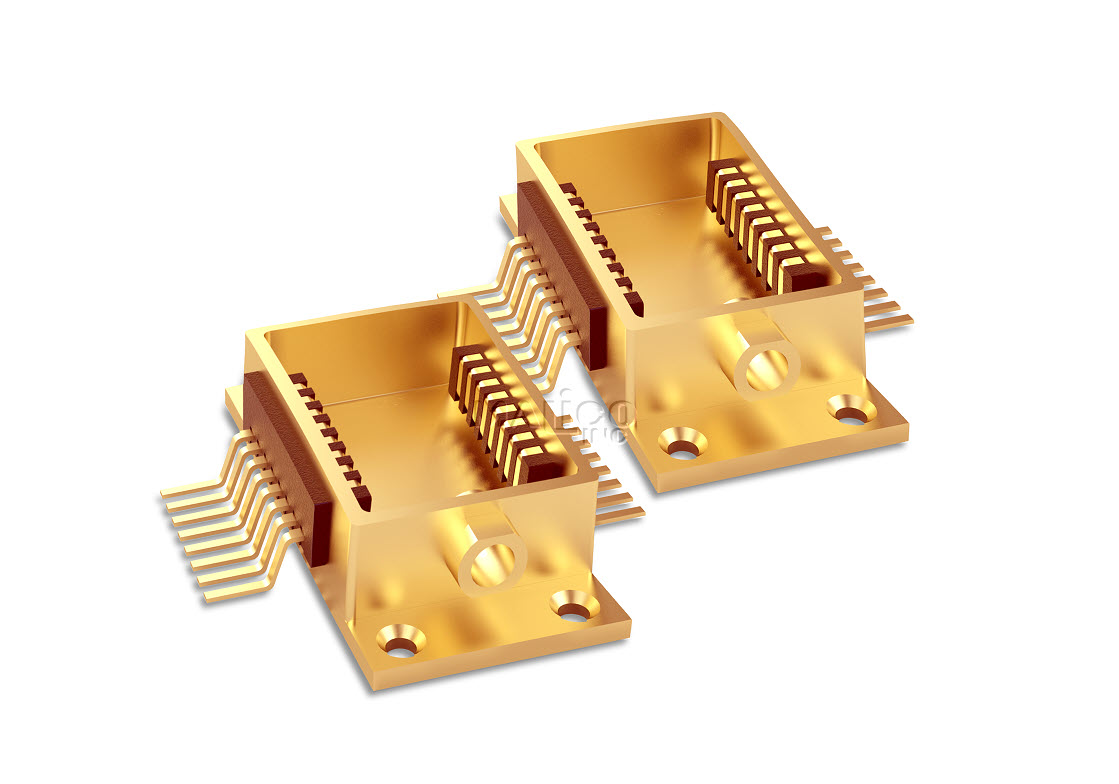

Tungsten Copper – low CTE and high thermal conductivity thermal solution for Fiber Optic Communication (OFC) application

Tungsten copper ( W-Cu ) material with its low CTE and high thermal conductivity is the preferred material in the industry to handle 5G and 6G transmissions.

Malico’s unique metal formatting capability can provide a complete one unit net shape/cost effective part to achieve the ultimate performance required.

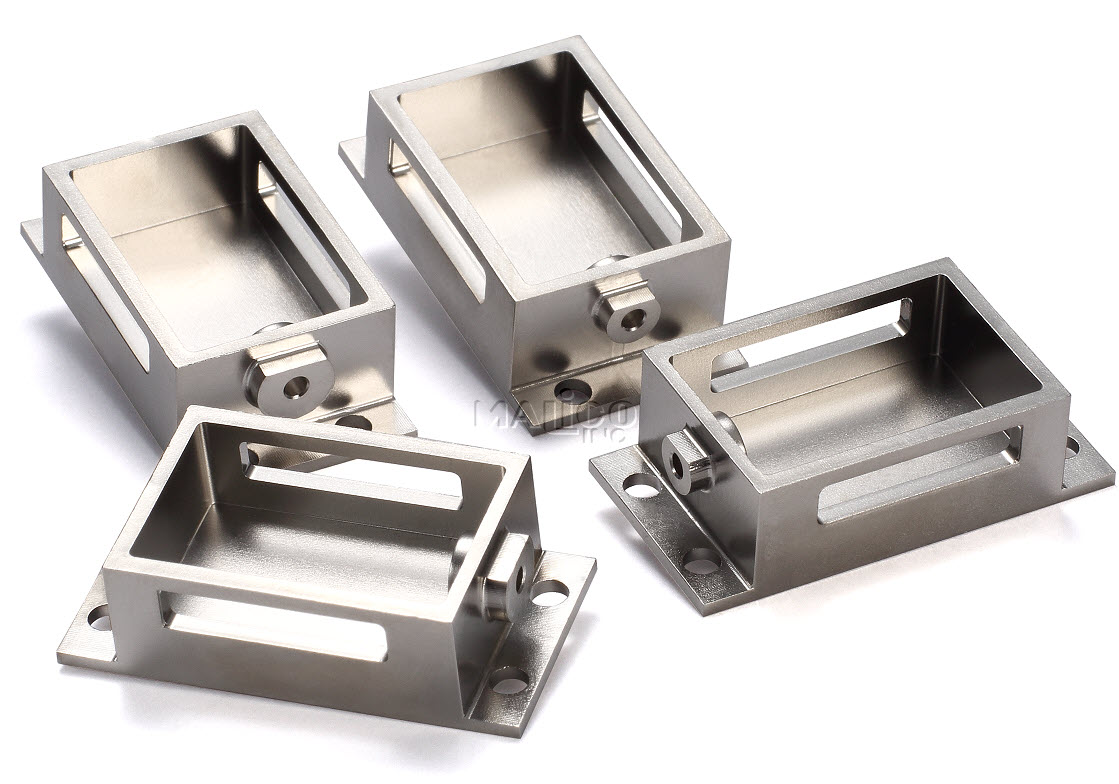

Semiconductor IC package testing and machine thermal solution

Nowadays, the functions of IC packages are increasing in every application which is adding more complexity to the package design. To meet the market demand, the semiconductor test equipment of the IC package must also increase its functionality accordingly. When performing the package test, whether Burn-in or FT (final test), keeping a proper temperature control of the testing rig is critical. An improper temperature control of the system will affect the stability of the test and can also cause a degradation to the ICs. Malico has many years of experience in the design of thermal management solutions and can provide optimized cooling channel design through CFD to solve the most challenging heat dissipation problem of IC testing machines.

Semiconductor plasma cleaning machine thermal solution

Plasma cleaning is a process that uses ionized gas to interact with a substrate to remove contamination and/or enhance its surface for further processing, which means the plasma cleaning machine is working under a high temperature environment that can make its components, such as the cooling element, prone to a corrosion attack. A typical cooling element has a relatively low lifetime and causes troubles easily. Malico cold plates treated with high-density anodization coating have excellent corrosion resistance to support your Plasma cleaning machine needs.