Copper Tungsten

Revolutionary breakthrough in Tungsten Copper alloy material forming

Tungsten-copper is a hard material, and the processing is not easy, with the need to frequently change the cutter due to wear, resulting in high product costs. Many people try to use PM or metal injection molding technology to form products, and the geometry of the products can make for poor material flow that cannot reach all areas. Some people try to add other metal materials (nickel) to improve the fluidity of the material but this greatly reduce its thermal conductivity.

Malico has invested a lot of money and R&D to develop a successful process after years of hard work.

Tungsten-copper is the only material that can be easily formed without adding other metal materials to aid the manufacturing process, and have a finished product being very close to the final desired geometric size. This material fully meets the characteristics of high thermal conductivity, high strength, high heat resistance and low expansion. This is a great revolutionary breakthrough in metallurgical technology.

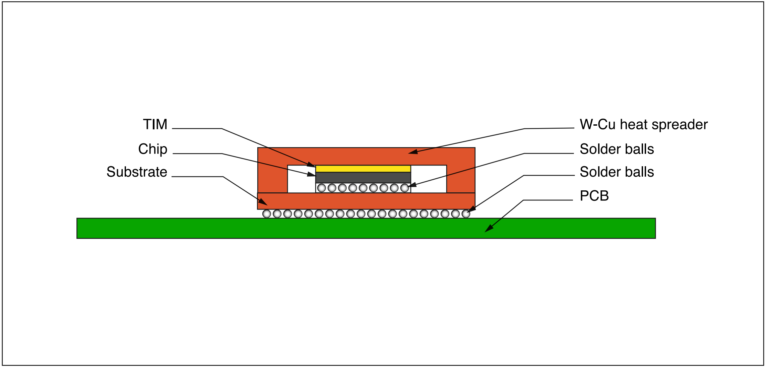

Malico’s ultra-thin “net-shaped” Tungsten Copper (W-Cu) heat spreader for actualization and advancement of high-end CSP & BGA packages.

Tungsten copper (W-Cu) composite provides the most integral value as a heat spreader or thermal lid for modern high-end IC packages and modules, for its properly low CTE, better-than-copper strength, and reasonably high thermal conductivity. A cost-effective cooling mechanism is, without a doubt, a necessity to the commercial success of high-end IC packages and high-speed-transmitting modules. Tungsten copper heat spreader is definitely one of the most critical elements for implementing structural integrity and thermal reliability of highly integrated and slim IC packages for the electronics, communication, automobile, aviation, military industries, etc.

*Please fill out the form and download.

Download Malico’s Tungsten-Copper Powder Metallurgy Innovation

Download Malico’s Tungsten-Copper Powder Metallurgy Innovation