Forge

Home »

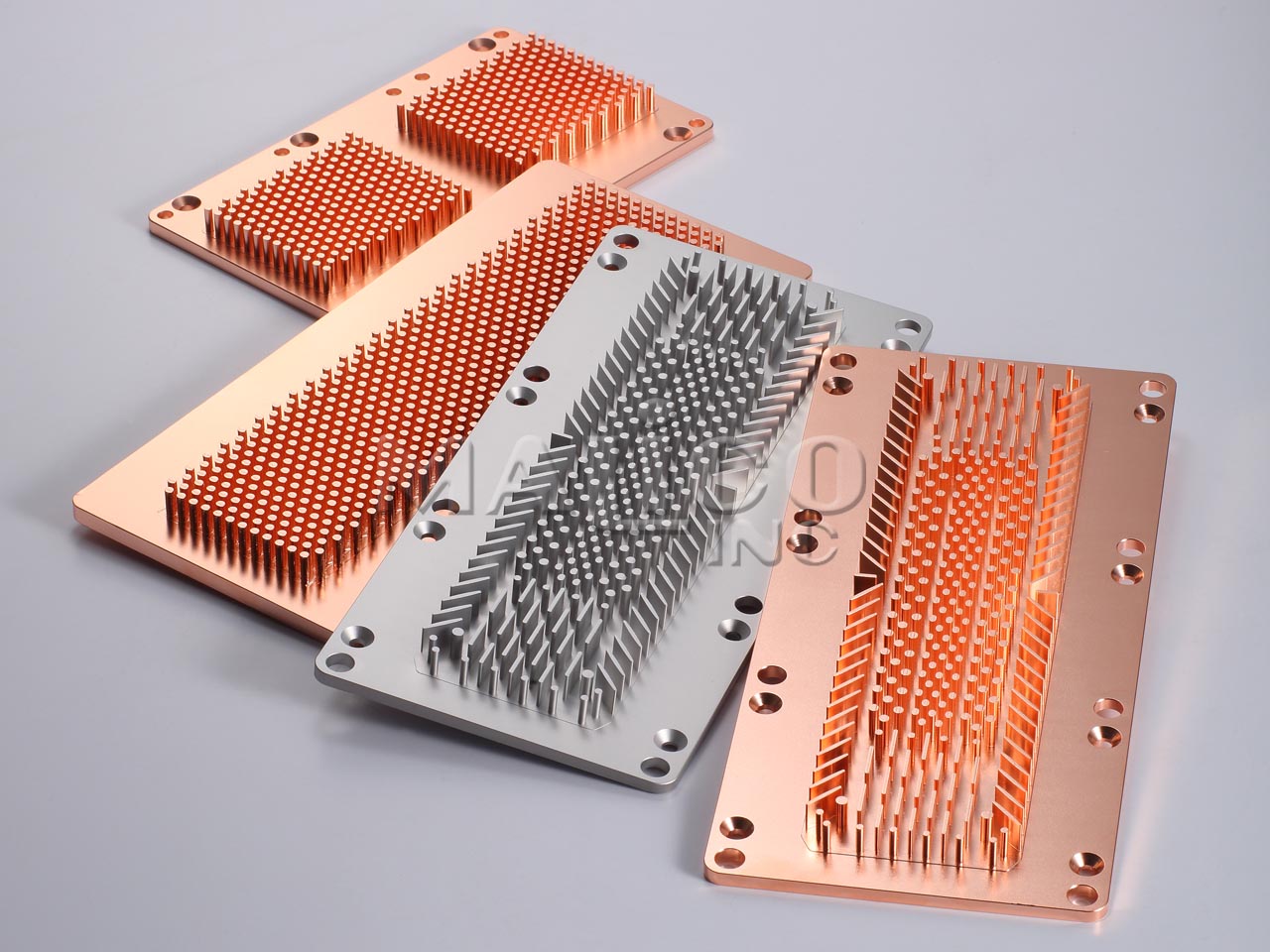

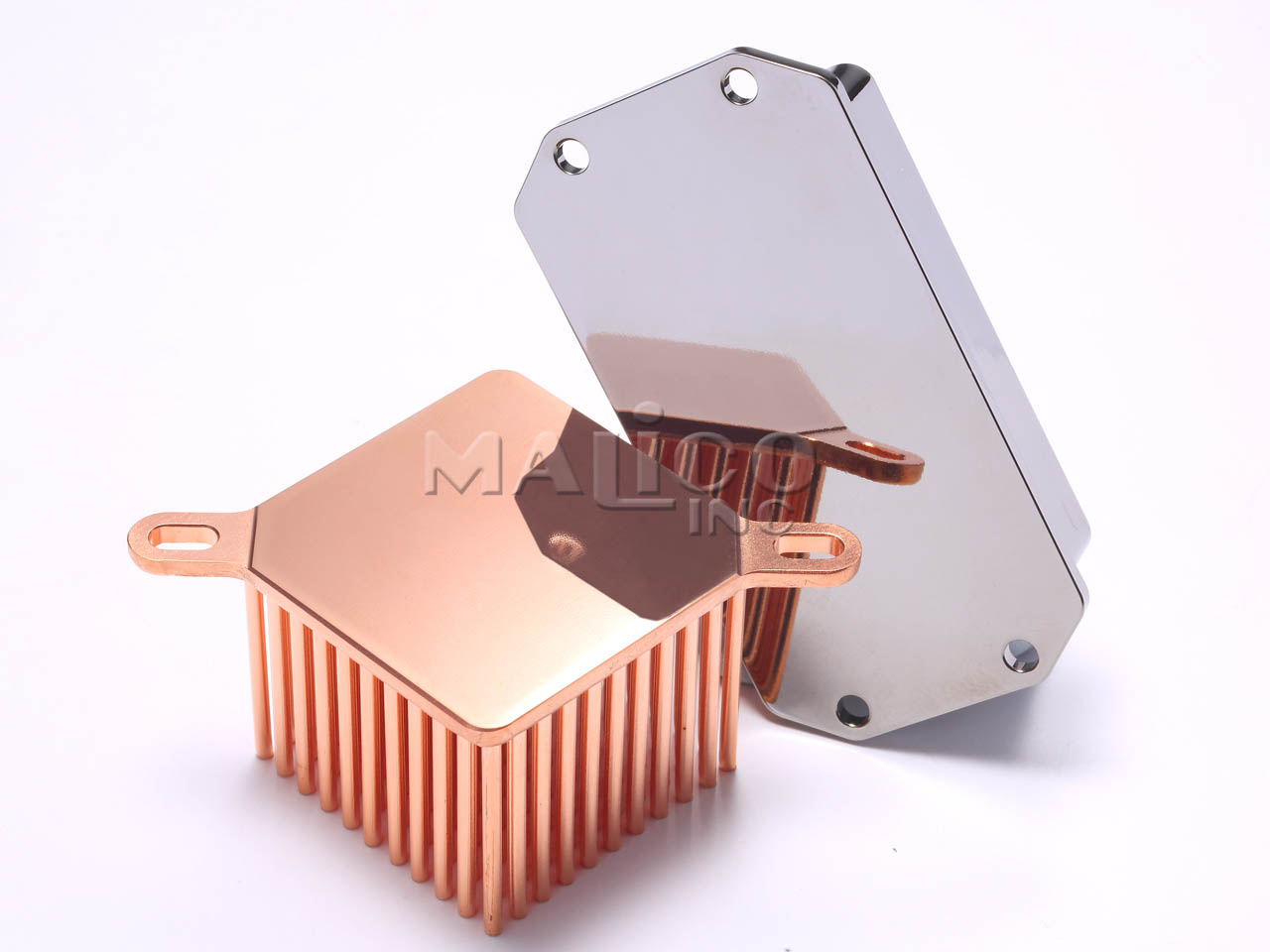

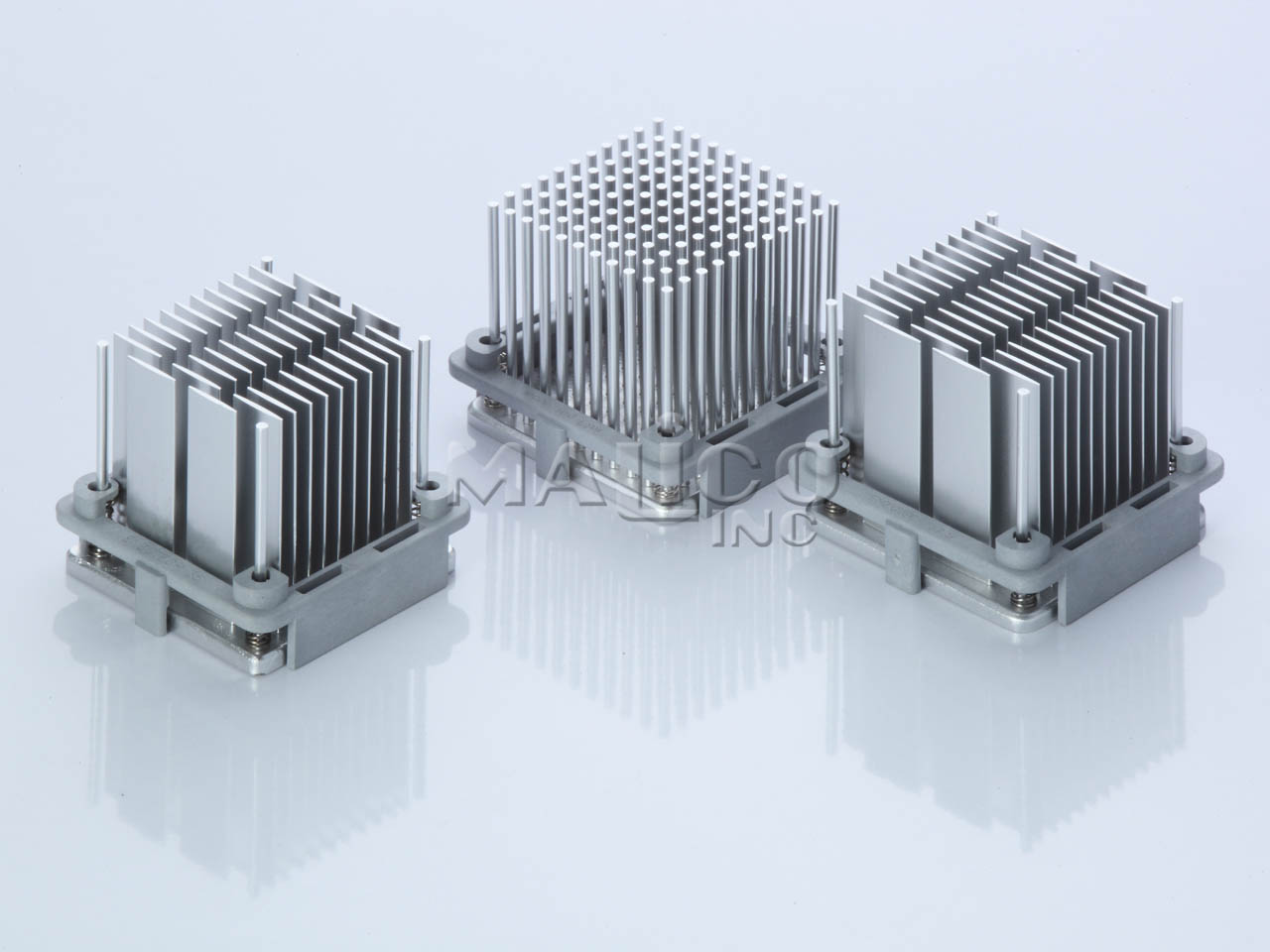

Forging Process

Our benefits:

- Complete in one piece with no interface.

- High aspect ratio 1:100

- It can forge aluminum alloy, pure aluminum, and copper

- No taper fin shape improves airflow smooth through

- High material density increases thermal conductivity

- It has the same wide range of geometry as die casting

- Fin or pin forge can form in one time doesn’t need cross-cutting

Malico has fully integrated horizontal and vertical operations. Our production lines are optimized to allow products to flow smoothly to guarantee fast delivery.

Our mission is to consistently provide our customers with high-quality products to help improve their turnaround time and profits.

Our vertically integrated production lines allow us to offer you the best quality, lead times, and costs.